Product information

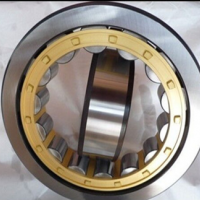

Deep Groove Ball Bearing Description

Deep groove ball bearings have high speed and are widely used as radial bearings. These non-separable

Bearings are available in a wide variety of seal, shield and snap-ring arrangements. Deep Groove Ball

Bearings are cost-effective and maintenance free. They are basically used when axial loads from two

Directions have to be transmitted & there is not enough space to allow installation of matched spindle bearings and when speed is less important when compared to required guidance of the rotating parts.

Physical Characteristics

· Comprises of deep uninterrupted raceways

· Ring grooves are circular arcs made slightly larger than the radius of the ball

· The balls make point contact with the raceways

· The inner ring shoulders are of equal height

Advantages of Deep Groove Ball Bearings

· Sustain radial, axial, or composite loads.

· Provide both high-running accuracy & high-speed operation

· Can replace high speed angular contact ball bearings

· Simple design

· Maintenance free

· Longer service life

| 6000 series | ||||

| Bearing | Inner dimension | Outside dimension | width | Weight |

| No. | d | D | W | Kg/pc |

| 6000 | 10 | 26 | 8 | 0.187 |

| 6001 | 12 | 28 | 8 | 0.0216 |

| 6002 | 15 | 32 | 9 | 0.030 |

| 6003 | 17 | 35 | 10 | 0.039 |

| 6004 | 20 | 42 | 12 | 0.067 |

| 6005 | 25 | 47 | 12 | 0.0743 |

| 6006 | 30 | 55 | 13 | 0.112 |

| 6007 | 35 | 62 | 14 | 0.146 |

| 6008 | 40 | 68 | 15 | 0.182 |

| 6009 | 45 | 75 | 16 | 0.229 |

| 6010 | 50 | 80 | 16 | 0.249 |

| 6011 | 55 | 90 | 18 | 0.374 |

| 6012 | 60 | 95 | 18 | 0.38 |

| 6013 | 65 | 100 | 18 | 0.43 |

| 6014 | 70 | 110 | 20 | 0.586 |

| 6015 | 75 | 115 | 20 | 0.63 |

| 6016 | 80 | 125 | 22 | 0.858 |

| 6017 | 85 | 130 | 22 | 0.88 |

| 6018 | 90 | 140 | 24 | 1.16 |

| 6019 | 95 | 145 | 24 | 1.18 |

| 6020 | 100 | 150 | 24 | 1.22 |

| 6021 | 105 | 160 | 26 | 1.56 |

| 6022 | 110 | 170 | 28 | 1.96 |

| 6024 | 120 | 180 | 28 | 2.05 |

| 6026 | 130 | 200 | 33 | 2.05 |

| 6028 | 140 | 210 | 33 | 3.9 |

| 6030E | 150 | 225 | 35 | 4.8 |

| 6032 | 160 | 240 | 38 | 5.9 |

| 6034 | 170 | 260 | 42 | 7.9 |

| 6036 | 180 | 280 | 46 | 10.65 |

| 6038 | 190 | 290 | 46 | 11.14 |

| 60340 | 200 | 280 | 51 | 14.8 |

| 6044 | 220 | 340 | 56 | 19 |

| 6200 series | ||||

| 6200 | 10 | 30 | 9 | 0.032 |

| 6201 | 12 | 32 | 10 | 0.037 |

| 6202 | 15 | 35 | 11 | 0.045 |

| 6203 | 17 | 40 | 12 | 0.066 |

| 6204 | 20 | 47 | 14 | 0.106 |

| 6205 | 25 | 52 | 15 | 0.128 |

| 6206 | 30 | 62 | 16 | 0.199 |

| 6207 | 35 | 72 | 17 | 0.287 |

| 6208 | 40 | 80 | 18 | 0.367 |

| 6209 | 45 | 85 | 19 | 0.416 |

| 6210 | 50 | 90 | 20 | 0.462 |

| 6211 | 55 | 100 | 21 | 0.602 |

| 6212 | 60 | 110 | 22 | 0.789 |

| 6213 | 65 | 120 | 23 | 0.990 |

| 6214 | 70 | 125 | 24 | 1.1 |

| 6215 | 75 | 130 | 25 | 1.2 |

| 6216 | 80 | 140 | 46 | 1.4 |

| 6217 | 85 | 150 | 28 | 1.92 |

| 6218 | 90 | 160 | 30 | 2.12 |

| 6219 | 95 | 170 | 32 | 2.61 |

| 6220 | 100 | 180 | 34 | 3.19 |

| 6221 | 105 | 190 | 36 | 3.66 |

| 6222 | 110 | 200 | 38 | 4.44 |

| 6224 | 120 | 215 | 40 | 5.11 |

| 6226 | 130 | 230 | 40 | 6.19 |

| 6228 | 140 | 250 | 42 | 9.44 |

| 6230 | 150 | 270 | 45 | 10.4 |

| 6232 | 160 | 290 | 48 | 15 |

| 6234 | 170 | 310 | 52 | 16.5 |

| 6236 | 180 | 320 | 52 | 17.8 |

| 6238 | 190 | 340 | 55 | 23 |

| 6240 | 200 | 340 | 58 | 24.8 |

| 6244 | 220 | 400 | 65 | 36.5 |

| 6248 | 240 | 440 | 72 | 53.9 |

| 6300 series | ||||

| 6300 | 10 | 35 | 11 | 0.053 |

| 6301 | 12 | 37 | 12 | 0.06 |

| 6302 | 15 | 42 | 13 | 0.082 |

| 6303 | 17 | 47 | 14 | 0.115 |

| 6304 | 20 | 52 | 15 | 0.144 |

| 6305 | 25 | 62 | 17 | 0.2193 |

| 6306 | 30 | 72 | 19 | 0.3498 |

| 6307 | 35 | 80 | 21 | 0.4542 |

| 6308 | 40 | 90 | 23 | 0.6394 |

| 6309 | 45 | 100 | 25 | 0.8363 |

| 6310 | 50 | 110 | 27 | 1.0822 |

| 6311 | 55 | 120 | 29 | 1.35 |

| 6312 | 60 | 31 | 1.7 | |

| 6313 | 65 | 140 | 33 | 2.1 |

| 6314 | 70 | 150 | 35 | 2.5 |

| 6315 | 75 | 160 | 37 | 3 |

| 6316 | 80 | 170 | 39 | 3.6 |

| 6317 | 85 | 180 | 41 | 4.22 |

| 6318 | 90 | 190 | 43 | 4.91 |

| 6319 | 95 | 200 | 45 | 5.7 |

| 6320 | 100 | 215 | 47 | 7.2 |

| 6321 | 105 | 225 | 49 | 7.84 |

| 6322 | 110 | 240 | 50 | 9.22 |

| 6324 | 120 | 260 | 55 | 14.78 |

| 6326 | 130 | 280 | 58 | 16.52 |

| 6328 | 140 | 300 | 62 | 22.76 |

| 6330 | 150 | 320 | 65 | 26 |

| 6332M | 160 | 340 | 68 | 26 |

| 6334 | 170 | 360 | 72 | 35.6 |

| 6350 | 200 | 420 | 80 | 59.2 |

| 6400 series | ||||

| 6403 | 17 | 62 | 17 | 0.224 |

| 6404 | 20 | 72 | 19 | 0.4 |

| 6405 | 25 | 80 | 21 | 0.53 |

| 6406 | 30 | 90 | 23 | 0.735 |

| 6407 | 35 | 100 | 25 | 0.952 |

| 6408 | 40 | 110 | 27 | 1.23 |

| 6409 | 45 | 120 | 29 | 1.53 |

| 6410 | 50 | 130 | 31 | 1.88 |

| 6411 | 55 | 140 | 33 | 2.29 |

| 6412 | 60 | 150 | 35 | 2.77 |

| 6413 | 65 | 160 | 37 | 3.3 |

| 6414 | 70 | 180 | 42 | 4.83 |

| 6415 | 75 | 190 | 45 | 5.72 |

| 6416 | 80 | 200 | 48 | 6.76 |

| 6417 | 85 | 210 | 52 | 7.95 |

| 6418 | 90 | 225 | 54 | 11.4 |

| 6419 | 95 | 240 | 55 | 13.4 |

| 6420 | 100 | 250 | 58 | 15.4 |

| 6422 | 110 | 280 | 65 | 19 |

| 62201 | 12 | 32 | 14 | |

| 62202 | 15 | 35 | 14 | |

| 62203 | 17 | 40 | 16 | |

| 62204 | 20 | 47 | 18 | |

| 62205 | 25 | 52 | 18 | |

| 62206 | 30 | 62 | 20 | |

| 62207 | 35 | 72 | 23 | |

| 62208 | 40 | 80 | 23 | |

| 62209 | 45 | 85 | 23 | |

| 62210 | 50 | 90 | 23 | |

| 62211 | 55 | 100 | 25 | |

| 62212 | 60 | 110 | 28 | |

| 62213 | 65 | 120 | 31 | |

| 62214 | 70 | 125 | 31 | |

| 62215 | 75 | 130 | 31 | |

| 62216 | 80 | 140 | 33 | |

| 62217 | 85 | 150 | 36 | |

| 88506 | 30 | 62 | 24 | 0.235 |

| 88507 | 35 | 72 | 25 | 0.33 |

| 88508 | 40 | 80 | 27 | 0.448 |

| 88509 | 45 | 85 | 27 | 0.498 |

| 88510 | 50 | 90 | 30 | 0.554 |

| 88511 | 55 | 100 | 31 | 0.76 |

| 88512 | 60 | 110 | 36 | 0.963 |

170314 170412 1000915 150212

Features and applications of deep groove ball bearings:

Deep groove ball bearing has simple structure, convenient use, which is the largest's production batch, the most widely used type of bearings. It is mainly used to bear radial load, also can absorb a certain amount of axial load. When bearing radial clearance increases, it has the function of angular contact ball bearings which can withstand greater axial load. Compared with the same size of other types of bearings, such bearing has small friction coefficient, high limit speed. In high speed under the condition of unfavorable use of thrust ball bearing, deep groove ball bearing can be used for carrying axial load.